Bin Lifter Product Range

Why a Bin Lifter or Tipper?

Bin lifters and tippers were designed as an effective tool to prevent back injuries while lifting and tipping wheelie bins

into larger skip bins. The cost of injury in Australia for the year 2012-13 was a staggering $28 Billion with lower back

injuries representing $4.8 Billion. While early bin lifters were effective in lifting and tipping bins, they were difficult

to use. In some cases, early models introduced new dangers such as scissor points and due to their method of

operation had to be attached to the receiving bin for stability.

The bin lifter is an ever-evolving product which is under constant scrutiny and change to meet new guidelines for

operator safety and electrical requirements where relevant.

into larger skip bins. The cost of injury in Australia for the year 2012-13 was a staggering $28 Billion with lower back

injuries representing $4.8 Billion. While early bin lifters were effective in lifting and tipping bins, they were difficult

to use. In some cases, early models introduced new dangers such as scissor points and due to their method of

operation had to be attached to the receiving bin for stability.

The bin lifter is an ever-evolving product which is under constant scrutiny and change to meet new guidelines for

operator safety and electrical requirements where relevant.

NIFTY-LIFT 30KG

Gas Strut Wheelie Bin Lift

|

The Nifty Lift is a manually operated bin-lifter that aids in the lifting and emptying of wheelie bins into skips, using gas struts to give 30Kg of assisted lifting force.

Designed to lift up to 30kg at a time, this bin-lifter is perfect for retail outlets, small offices and factories that dispose of paper and general waste and are required to empty their wheelie bins once or twice a day. The lifting action is a “full swing” tip operation which enables it to be compact in size.

|

Ecolift 50kg

Manual Wheelie Bin Lifter

The Ecolift 50 is the ideal unit for anybody who has to lift light weights infrequently. Designed to lift up to 50kg at a time, the Ecolift is perfect for schools, small offices and local councils that dispose of paper waste and are required to empty the wheelie bin once or twice a day. The Ecolift eliminates all lifting from the process of empting wheelie bins into larger dumper bins. The bin is lifted by simply manually rotating the crank handle. The user is protected against costly back injuries. The Ecolift 50 is designed and manufactured in Australia using the highest quality components. The dimensions of 1202L x 798W (including crank handle) x 2002H ensure easy storage and the castors allow for effortless mobility. The frame has a powder coated finish for weather resistance. |

EZI-MT™ 65KG

Manual Wheelie Bin Lifter

|

The Ezi-MT is an economically-priced manual bin lifter from Crackerjack Industries that takes the strain out of emptying bins, making it a safe and easy operation.

The Ezi-MT has a large 65kg lifting capacity, yet is also lightweight and easy to move, making it the perfect solution for small businesses, schools, cafes, offices and local councils. With the reliable and economic Ezi-MT there is no longer an excuse - safety no longer costs - it pays! FEATURES

|

|

MULTI-TIP™

Hydraulic Wheelie Bin Lifter

|

The Multi-Tip bin-tipper from Crackerjack Industries is everything a bin tipper should be - safe, economic, easy to use, versatile, and efficient. Perfect for light industrial use to empty bins at schools, factories, recycling centres and more.

FEATURES

|

OPTIONS

|

DUMPMASTER™

Hydraulic Wheelie Bin Lifter

|

Dumpmaster™ wheelie-bin tippers are the ultimate solution to empty bins and drums weighing up to 300kg at virtually any height.

The tipping action of a Dumpmaster is one of the safest, most efficient, and easiest to use systems in the world. Dumpmasters are highly versatile and can be used in numerous applications, ranging from emptying rubbish bins into skips to pouring food ingredients into hoppers or mixers. No matter what the application, Dumpmasters have proven to be safe, reliable and economical to operate, year after year. Dumpmaster bin lifters have a unique tipping action whereby bins are lifted straight up, and then gently rolled forward around the lip of the skip or hopper being emptied into. If you need bin-lifters that accommodate wider or heavier bins have a look at our MegaDumper Series. FEATURES

|

OPTIONS

|

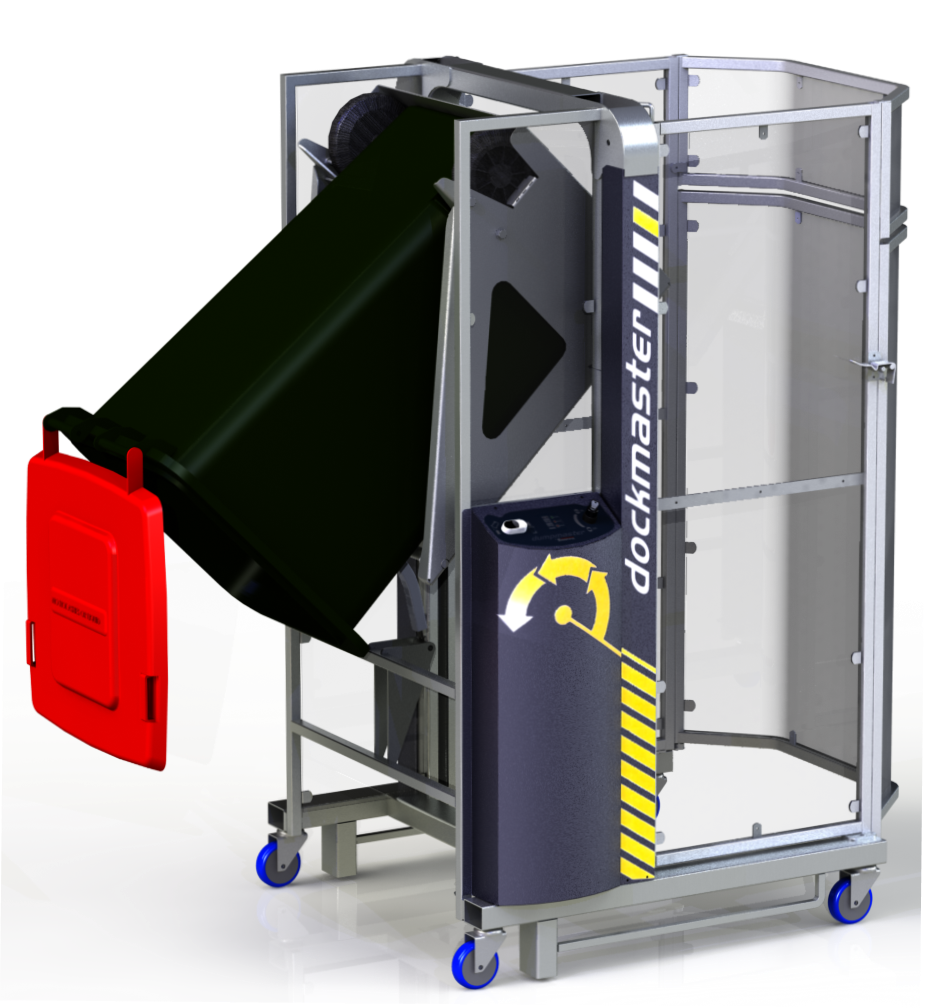

DOCKMASTER™

Wheelie Bin Tipper for raised platforms

|

The Dockmaster was designed with a specific task in mind - safely tipping wheelie bins and drums from a raised loading dock. In many operations this is currently done by hand, which is difficult, slow and dangerous. The Dockmaster completes the process in seconds and is fully compliant with stringent new safety requirements. The Dockmaster is based on the proven design of the Simpro Dumpmaster, but with unique features. The tipping mechanism inverts bins as low to the ground as possible, at just 700mm, while still keeping the weight within the footprint of the machine. To allow operating near platform edges the Dockmaster is fitted with safety feet, just behind the wheels. These catch the machine if it is rolled over the edge, instantly preventing further movement. The Dockmaster is built to the same rugged specifications as the Dumpmaster, including the steel frame, powerpack and control system. It will effortlessly tip most types of wheelie bin at weights up to 250kg, and is designed to withstand many years of operation indoors or outdoors. OPTIONS The Dockmaster is compatible with most Dumpmaster options and accessories, including:

|

MEGADUMPER™

Heavy-Duty Industrial Bin Lifter

|

MegaDumper employs the same efficient tipping geometry as the well-proven Dumpmaster machines. They are available with cradles to suit a range of larger bins, including 660l, 1000/1100l wheelie bins, or square and rectangular bins. Attachments are available to enable multiple bin sizes to be tipped, for example a cradle for tipping 1100l bins can be fitted with auxiliary catches to enable all standard wheelie bins from 80 litres up to 660 litres to be tipped as well. No adjustment is required for tipping the different sizes – simply wheel the bin in and empty it!

MegaDumpers can be made to tip at any practical height. They normally have a hot-dip galvanised frame and cradle, with zinc-plated guarding. However, some or all of the machine components can be made from stainless-steel for use in hygiene-critical areas or harsh environments. OPTIONS

|

|

Although we offer fixed pricing on our products, freight charges will inevitably vary. Please note, delivery and availability varies between cities. Not all regional areas can be serviced. Please use the form below to tell us what you need and where you are located. We will confirm availability. This is not an order form.

Request for Quotation

If you prefer to speak with someone, phone Clive O'Connor.